Cooling fans play a vital role in thermal management across a variety of devices and systems. When it comes to equipment operating on standard mains electricity, the 220V cooling fan becomes a preferred choice for its compatibility, efficiency, and direct plug-in capability. These fans are commonly found in industrial enclosures, automation systems, power distribution cabinets, refrigeration equipment, and more. Selecting the right 220V cooling fan involves more than matching voltage—it requires attention to performance, durability, design, and specific operating conditions.

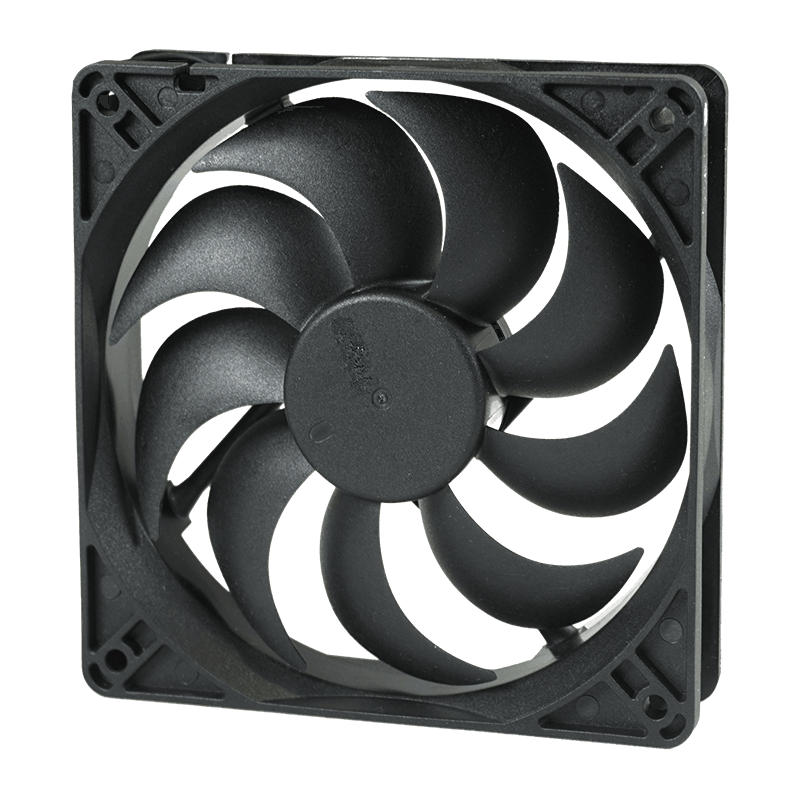

These fans are generally axial or centrifugal in design and are used for ventilation, heat dissipation, and maintaining airflow in enclosed or semi-enclosed spaces.

Key Factors in Selection

1. Airflow Requirements (CFM or m³/h)

The primary function of a cooling fan is to move air, and airflow capacity is usually measured in:

CFM (Cubic Feet per Minute) or

m³/h (Cubic Meters per Hour)

Selecting the right airflow depends on:

The size of the enclosure or system

The heat load generated by the equipment

The required temperature range

A fan with insufficient airflow may overheating, while one with excessive flow might consume unnecessary energy or create excessive noise.

2. Fan Type: Axial vs. Centrifugal

Axial Fans: Move air along the axis of rotation. They are compact and efficient for general ventilation and cooling in shallow enclosures.

Centrifugal (Blower) Fans: Expel air at a 90-degree angle and are suitable for ducted systems or when higher pressure is needed.

Axial fans are more common for simple applications, while centrifugal fans are used when air needs to be directed or moved over longer distances.

3. Size and Mounting Configuration

220V cooling fans are available in multiple sizes, with common dimensions including:

80mm x 80mm

120mm x 120mm

150mm x 150mm

Larger sizes for industrial applications

Before selecting, check:

Available space in the enclosure or equipment

Mounting hole patterns and alignment

Depth (thickness) of the fan, which can affect airflow and noise

Standardized sizes simplify replacement and integration into existing systems.

4. Bearing Type and Lifespan

The bearing system of a fan influences its noise level, operating orientation, and service life.

Sleeve Bearings: Quiet and cost-effective, but typically have shorter lifespans and perform better in horizontal positions.

Ball Bearings: Longer life and better performance in high-temperature or vertical installations.

Dual Ball Bearings or Advanced Systems (e.g., FDB): Provide high durability for industrial or continuous operation environments.

For long-term reliability, especially in demanding conditions, ball bearings are a preferred option.

5. Noise Level

Noise is a key factor, especially in office, medical, or indoor industrial environments. Noise is typically rated in decibels (dB), with lower values indicating quieter operation.

Larger fans often move more air at lower RPMs, producing less noise.

Blade design, material, and housing shape also affect acoustic performance.

If low noise is essential, consider fans with optimized blade geometry and noise-reducing features.

6. Material and Build Quality

Frame and blade materials influence the fan's strength, temperature resistance, and corrosion resistance.

Plastic (usually PBT): Lightweight and flame-retardant, commonly used in standard applications.

Aluminum: Used in heavy-duty or high-temperature models for better heat resistance and structural strength.

Durability and environmental exposure should guide material selection.

7. Safety and Certifications

Ensure the fan complies with regional electrical safety standards. Look for certifications such as:

CE (Europe)

UL (USA)

RoHS Compliance (for restricted hazardous substances)

These standards assure safe and environmentally responsible operation.

8. Additional Features

Some 220V cooling fans come with features that enhance usability:

Thermal Cutoff or Temperature Sensors

Finger Guards or Filters

Speed Controllers

Moisture or Dust Protection Ratings (e.g., IP54, IP65)

Select features based on the specific environment and application conditions.

English

English 中文简体

中文简体 عربى

عربى