AC axial flow fans are widely used in various industries due to their efficiency in moving large volumes of air across long distances. These fans, typically powered by alternating current (AC), have blades mounted on a rotor that moves air along the axis of the fan. The design and functionality of these fans make them suitable for a wide range of applications, from cooling systems in industrial plants to ventilation systems in buildings.

1. Standard AC Axial Flow Fans

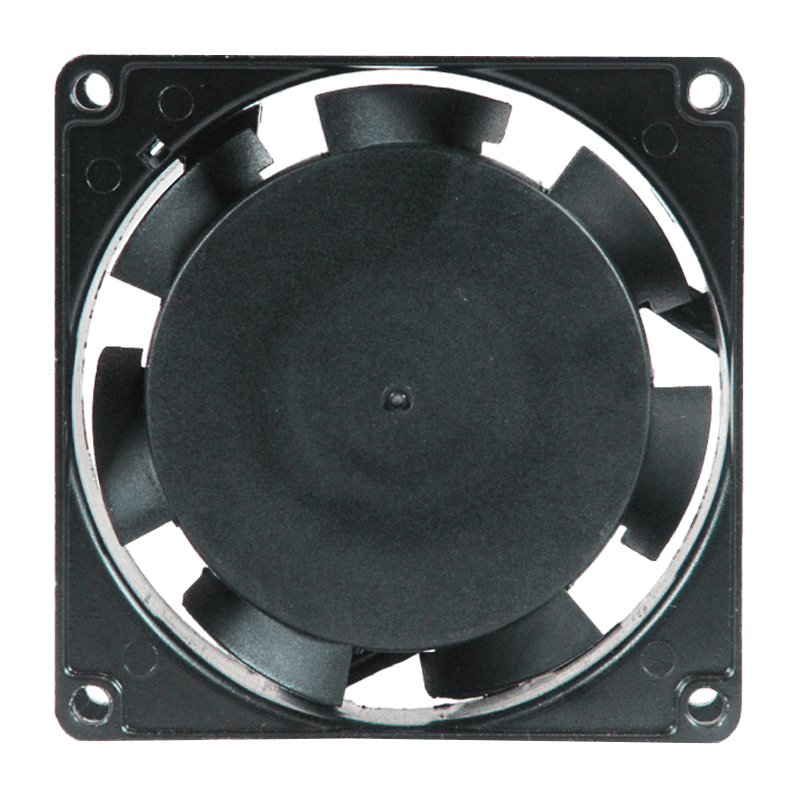

Standard AC axial flow fans are the common and widely used type of axial fan. They are characterized by their simple design, which consists of a rotor with blades attached to it, mounted in a cylindrical casing. These fans are designed to move air efficiently in a straight line along the axis of the fan.

Advantages:

High Airflow: Standard axial fans are capable of moving a large volume of air at a relatively low pressure, making them ideal for general ventilation and cooling applications.

Energy Efficiency: These fans are relatively energy-efficient due to their simple design, which minimizes friction losses and power consumption.

Compact Design: Their compact design allows them to be installed in tight spaces, making them versatile for various applications.

Typical Applications:

Industrial Cooling: Used to cool machinery, equipment, or industrial processes.

Ventilation Systems: Common in HVAC systems for general air circulation in buildings, tunnels, and underground spaces.

Drying Systems: Used in drying applications in industries such as food processing, pharmaceuticals, and textiles.

Standard AC axial flow fans are a reliable choice for basic airflow needs, especially in environments where space is limited and large air volumes are required.

2. High-Pressure AC Axial Flow Fans

High-pressure AC axial flow fans are designed for applications that require higher static pressure. These fans have blades that are more aerodynamically shaped, allowing them to push air against higher resistance while maintaining efficient airflow.

Advantages:

Higher Static Pressure: These fans are capable of overcoming higher resistance, making them ideal for applications where airflow must be forced through filters, ducts, or other restrictive environments.

Robust Design: High-pressure axial fans typically feature reinforced casings and motors to handle the increased load and ensure durability under demanding conditions.

Optimized Airflow Efficiency: Despite their higher pressure, these fans still maintain a relatively high airflow rate, making them efficient for their intended purpose.

Typical Applications:

Industrial Ventilation: Used in environments where the airflow is obstructed by filters, ducts, or other barriers, such as in power plants or chemical processing facilities.

Air Handling Units: Found in systems that require a combination of high-pressure airflow and filtration, such as clean rooms or laboratories.

Heating, Ventilation, and Air Conditioning (HVAC): These fans are often used in HVAC systems that need to circulate air through complex ductwork or air filtration systems.

High-pressure AC axial flow fans are suitable for industrial or commercial applications that involve higher resistance or require air to be pushed through long ducts.

3. Explosion-Proof AC Axial Flow Fans

Explosion-proof AC axial flow fans are designed for use in environments where there is a risk of explosive gases or dust. These fans are built with safety features to prevent any sparks or heat generated by the motor from igniting flammable substances in the air.

Advantages:

Safety: Explosion-proof fans are designed to meet stringent safety standards and are built with special enclosures that prevent sparks or overheating, making them safe to use in hazardous environments.

Durability: These fans are typically constructed from corrosion-resistant materials and have robust motors that are capable of operating in conditions.

Reliable Performance: Explosion-proof fans are designed for continuous operation, providing reliable airflow in hazardous environments where failure could bring about serious consequences.

Typical Applications:

Petrochemical and Chemical Plants: Used in facilities where flammable gases or vapors are present, such as oil refineries, gas stations, or chemical manufacturing plants.

Mining Operations: Applied in underground mining, where explosive dust or gases can accumulate and pose a risk to personnel.

Pharmaceutical and Food Processing Industries: Used in areas where the production process generates potentially explosive dust or particles.

Explosion-proof AC axial flow fans are critical for maintaining safe and reliable airflow in hazardous environments, where the risk of fire or explosion is present.

English

English 中文简体

中文简体 عربى

عربى