The design of the 12038 fan blade is a critical factor that influences the fan's performance, efficiency, noise levels, and durability. The term "12038 fan" typically refers to a fan measuring 120mm by 120mm with a thickness of 38mm, commonly used in electronics cooling, HVAC systems, and various industrial applications.

One of the primary considerations in 12038 fan blade design is the blade shape. The geometry of the blades affects the volume of air moved (airflow) and the pressure generated by the fan. Curved blades are often used in these fans to enhance aerodynamic efficiency, allowing smooth airflow with reduced turbulence. The curvature also helps in directing the air in a consistent stream, which is essential for effective cooling in confined spaces like computer cases or ventilation ducts. The blade shape must balance between airflow and noise, as aggressive blade angles can increase turbulence and noise levels.

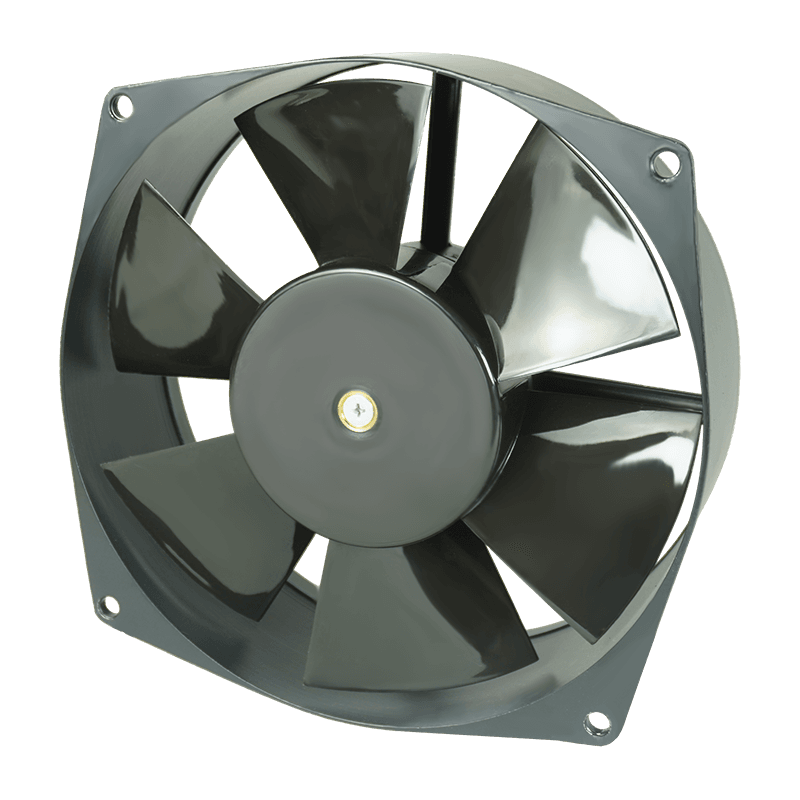

The number of blades on a 12038 fan also significantly impacts performance. Many 12038 fans feature between 7 to 9 blades, although some specialized designs may have more or fewer. More blades generally mean higher airflow and pressure but can also increased resistance and noise. Fewer blades might reduce noise but may not provide sufficient airflow for demanding cooling applications. Designers must find an number that meets the required performance specifications while maintaining acceptable noise levels.

Material selection is another important aspect of the 12038 fan blade design. Common materials include various plastics such as ABS or PBT, chosen for their strength, lightweight, and resistance to heat and chemicals. The material affects the blade's durability and resistance to warping or cracking under continuous operation. Some high-performance 12038 fans use reinforced plastics or composite materials to enhance stiffness and longevity without adding excessive weight.

Blade thickness and edge design are also critical. Thicker blades provide structural strength but add weight, which can reduce efficiency and increase power consumption. On the other hand, very thin blades may be prone to flexing or damage during operation. The edges of the blades are often designed with a slight taper or rounded finish to reduce noise generated by air friction and turbulence. Smooth edges help in maintaining steady airflow and reducing the fan's overall acoustic footprint.

The angle of attack, or the pitch of the blades, is essential in controlling how much air the 12038 fan moves and how much pressure it generates. A steeper blade angle pushes more air but requires more motor power and tends to produce more noise. Conversely, a shallower blade angle offers quieter operation and lower power consumption but reduces airflow. This angle is carefully chosen to balance airflow, noise, and power efficiency based on the fan's intended application.

The aerodynamics of the blade surface also play a role. Some designs incorporate ridges or small aerodynamic features on the blades to control airflow and reduce vortices that cause noise and energy loss. These surface modifications can enhance the fan's efficiency and quietness without major changes in size or power requirements.

The hub size of the 12038 fan blade is another design aspect that influences performance. A larger hub reduces the effective blade length and can decrease airflow, but it provides space to house a more robust motor or bearings. A smaller hub increases the blade area exposed to the air, improving airflow but limiting motor size. The hub size is typically optimized to accommodate the fan's motor while blade effectiveness.

English

English 中文简体

中文简体 عربى

عربى