EC cooling fans are essential components in various applications, including HVAC systems, data centers, and industrial equipment. These fans combine electronically commutated motors with advanced aerodynamic designs, providing high efficiency and precise airflow control. Understanding the types of EC cooling fans and the materials used in their construction helps engineers, operators, and system designers select the right fan for each application.

1. Axial EC Cooling Fans

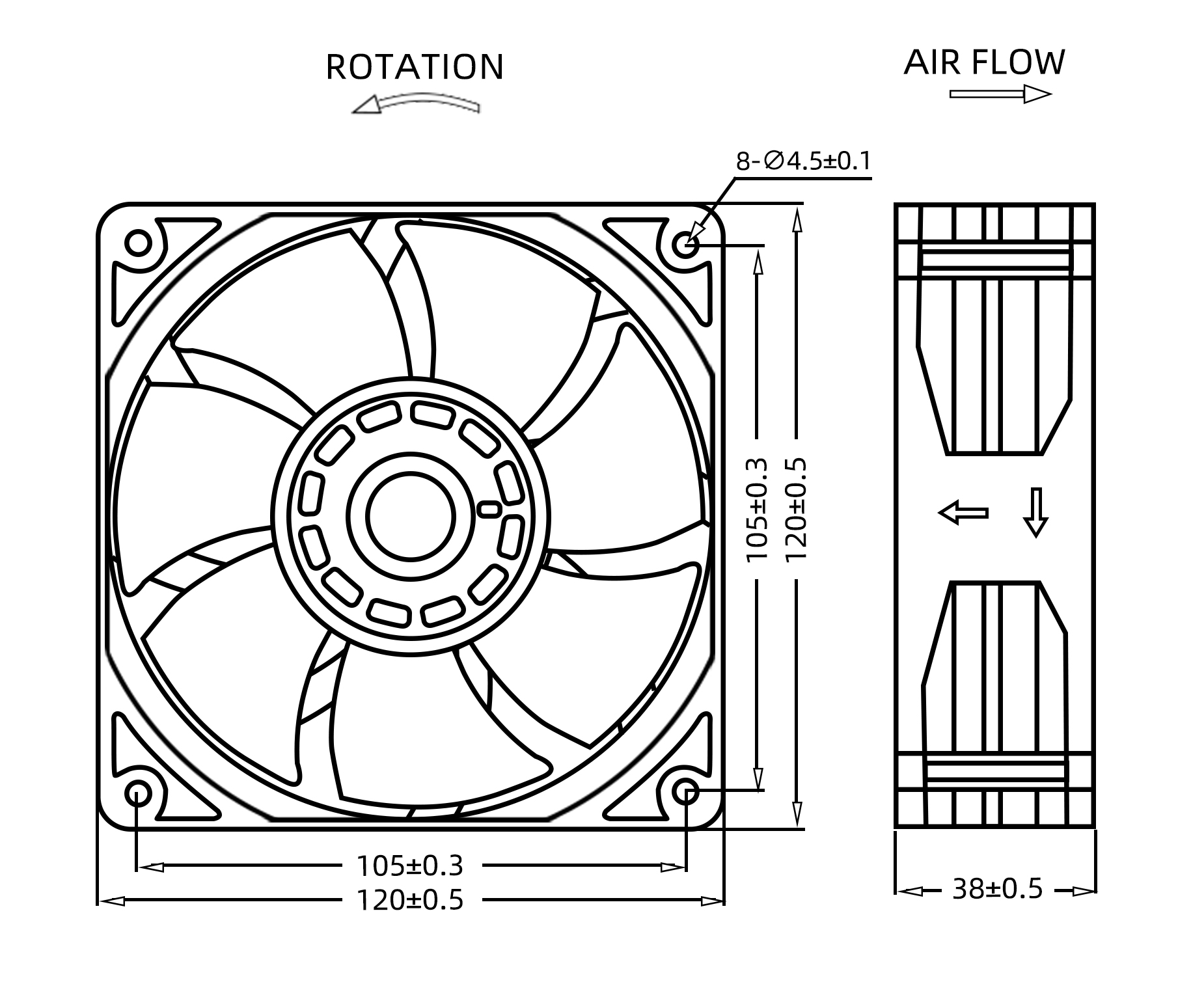

Design: Air flows parallel to the axis of rotation, providing high airflow at low pressure.

Applications: Commonly used in ventilation systems, cooling towers, and electronic cabinets.

Materials: Typically made from high-grade plastics or lightweight aluminum.

Expanding on these points, axial EC cooling fans are designed to move large volumes of air efficiently. Their blades push air in a straight line along the fan's axis, making them suitable for applications requiring moderate pressure but high airflow. The materials used in these fans are carefully selected for durability and lightweight properties. Plastics provide cost-effective solutions while resisting corrosion, whereas aluminum offers improved strength and heat dissipation. Axial EC cooling fans are widely preferred in HVAC systems and electronics cooling because they combine energy efficiency with reliable performance.

2. Centrifugal EC Cooling Fans

Design: Air enters the fan impeller axially and exits radially, generating higher pressure.

Applications: Ideal for ducted systems, industrial equipment, and high-resistance airflow scenarios.

Materials: Often constructed from steel, aluminum, or reinforced plastics.

Expanding on these points, centrifugal EC cooling fans are designed to overcome resistance in ducted or confined systems. The radial airflow allows these fans to maintain consistent performance under varying load conditions, making them suitable for industrial and commercial applications where airflow needs to be directed through ducts or filters. Material selection ensures durability and efficiency: steel provides structural strength, aluminum combines light weight and heat management, and reinforced plastics resist corrosion while maintaining sufficient rigidity. Centrifugal EC cooling fans are recognized for their reliability and versatility in demanding environments.

3. Mixed Flow EC Cooling Fans

Design: Combines features of axial and centrifugal fans for balanced airflow and pressure.

Applications: Used in air conditioning units, heat exchangers, and electronic cooling systems.

Materials: Typically manufactured from plastics, aluminum, or composite materials.

Expanding on these points, mixed flow EC cooling fans are engineered to provide moderate pressure and high airflow, combining the strengths of axial and centrifugal designs. The mixed flow impeller allows for efficient air movement while maintaining relatively low noise levels, making these fans ideal for both residential and commercial applications. The materials used in their construction are chosen for durability, corrosion resistance, and weight efficiency. Plastics are often preferred for cost-effective solutions, aluminum for thermal conductivity and strength, and composite materials for a combination of both. Mixed flow fans are versatile, energy-efficient, and suitable for various cooling requirements.

4. Custom and Specialty EC Cooling Fans

Design: Tailored to specific operational requirements, including size, airflow, and pressure.

Applications: Found in medical equipment, server rooms, and specialized industrial machinery.

Materials: Can include specialized plastics, aluminum alloys, or stainless steel for enhanced performance.

Expanding on these points, some EC cooling fans are custom-designed to meet unique operational needs. Manufacturers can adjust the fan size, blade design, and housing to achieve the required airflow, pressure, and noise level for specialized applications. Material choices are equally adaptable, ranging from advanced plastics for corrosion resistance to aluminum alloys for strength and lightweight construction. Stainless steel is sometimes used for hygiene-sensitive or high-temperature applications. Custom EC cooling fans provide tailored solutions while maintaining the efficiency and reliability associated with standard EC fan designs.

English

English 中文简体

中文简体 عربى

عربى