The 220V Cooling Fan is a critical component in various industrial and electronic systems. Its primary function is to dissipate heat and maintain ideal temperatures, ensuring the efficiency and longevity of equipment. When designing a 220V Cooling Fan, there are several key considerations that must be taken into account to ensure its effectiveness.

Power and Efficiency

1. Voltage Requirements

2. Efficiency in Energy Consumption

3. Longevity and Durability

Expansion:

The design consideration for a 220V Cooling Fan is its power requirements. As the name suggests, a 220V Cooling Fan is designed to operate at 220 volts, which is a standard voltage in many countries. This standardization ensures compatibility with a wide range of systems and reduces the need for voltage converters. However, within this voltage range, the fan's efficiency in energy consumption is crucial. A well-designed 220V Cooling Fan should consume minimal power while providing ideal cooling performance. This balance is achieved through the use of high-quality components and efficient motor designs that minimize energy loss and maximize air movement.

Longevity and durability are also key factors in the design of a 220V Cooling Fan. The fan should be able to operate continuously for extended periods without failure, which requires robust construction and the use of materials that can withstand high temperatures and wear. This durability not only ensures the fan's reliability but also reduces maintenance costs and downtime for the systems it is cooling.

Noise and Vibration

1. Reduction of Noise Levels

2. reduce Vibration

3. Acoustic and Mechanical Design

Expansion:

Noise and vibration are often overlooked aspects of 220V Cooling Fan design, but they are critical for maintaining a comfortable and efficient operating environment. A high-quality fan should operate with minimal noise, which can be achieved through careful design of the fan blades and motor. By optimizing the aerodynamics of the blades and using materials that dampen sound, a 220V Cooling Fan can be designed to produce less noise without sacrificing performance.

Vibration is another factor that can impact the performance and longevity of a 220V Cooling Fan. Excessive vibration can wear and tear on the fan's components, premature failure. To minimize vibration, the fan's motor and bearings must be balanced and designed to absorb shock. Additionally, the fan's housing should be sturdy enough to resist deformation under the stress of continuous operation.

Size and Portability

1. Compact Design

2. Ease of Integration

3. Portability for Mobile Applications

Expansion:

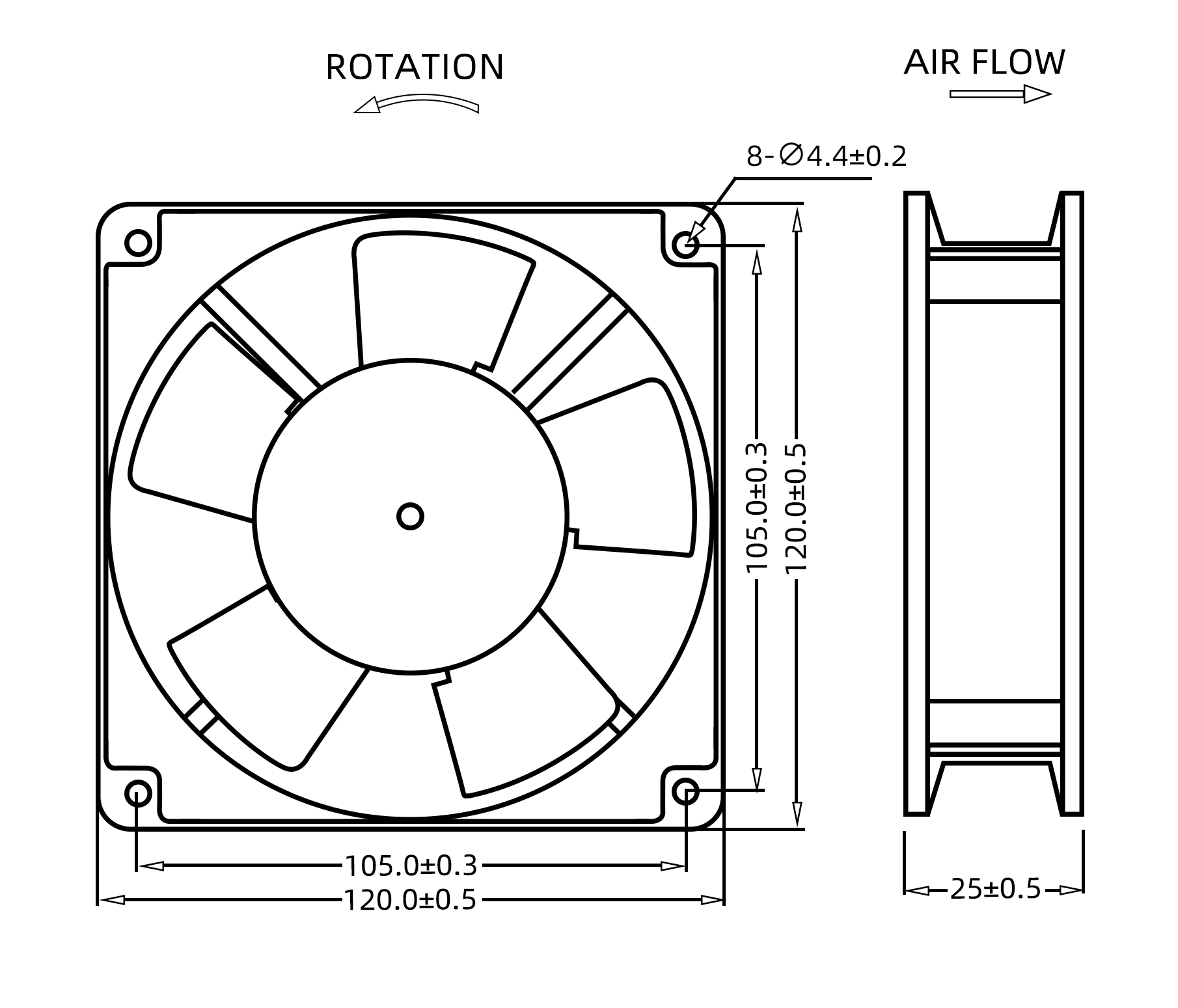

The size of a 220V Cooling Fan is an important consideration, especially in applications where space is at a premium. A compact design allows the fan to be easily integrated into various systems without taking up excessive space. This is particularly important in electronics and industrial applications where multiple components must fit within a confined area.

Ease of integration is another aspect of size that designers must consider. A 220V Cooling Fan should be designed with standard mounting points and dimensions that allow it to be easily installed and replaced in existing systems. This compatibility ensures that the fan can be used in a wide range of applications without requiring custom modifications.

Portability is also a consideration for some 220V Cooling Fan applications. In scenarios where the fan needs to be moved frequently, such as in mobile or temporary setups, a lightweight and easily transportable design is beneficial. This portability allows the fan to be used in various locations without the need for permanent installation, offering flexibility in its use.

English

English 中文简体

中文简体 عربى

عربى