Axial flow fans are widely used in industrial, commercial, and ventilation applications due to their efficiency in moving large volumes of air. Among the various models available, the 200FZY axial flow fan is notable for its reliable performance, versatility, and adaptability to different environments.

Overview of 200FZY Axial Flow Fans

The 200FZY axial flow fan is a type of ventilating fan designed to move air along the axis of the fan. Unlike centrifugal fans that redirect airflow at a right angle, axial fans generate airflow parallel to the axis of rotation, providing high airflow rates with relatively low pressure. These fans are commonly used in factories, tunnels, warehouses, agricultural facilities, and HVAC systems. Their simple structure, energy efficiency, and ability to handle large air volumes make them ideal for various ventilation tasks.

Key Characteristics of 200FZY Axial Flow Fans

Several features define the performance and suitability of 200FZY axial flow fans:

1. High Airflow Efficiency

200FZY fans are designed to deliver high airflow with minimal energy consumption. Their blade design optimizes air movement while reducing turbulence, resulting in consistent performance across different operational conditions.

2. Structural Design

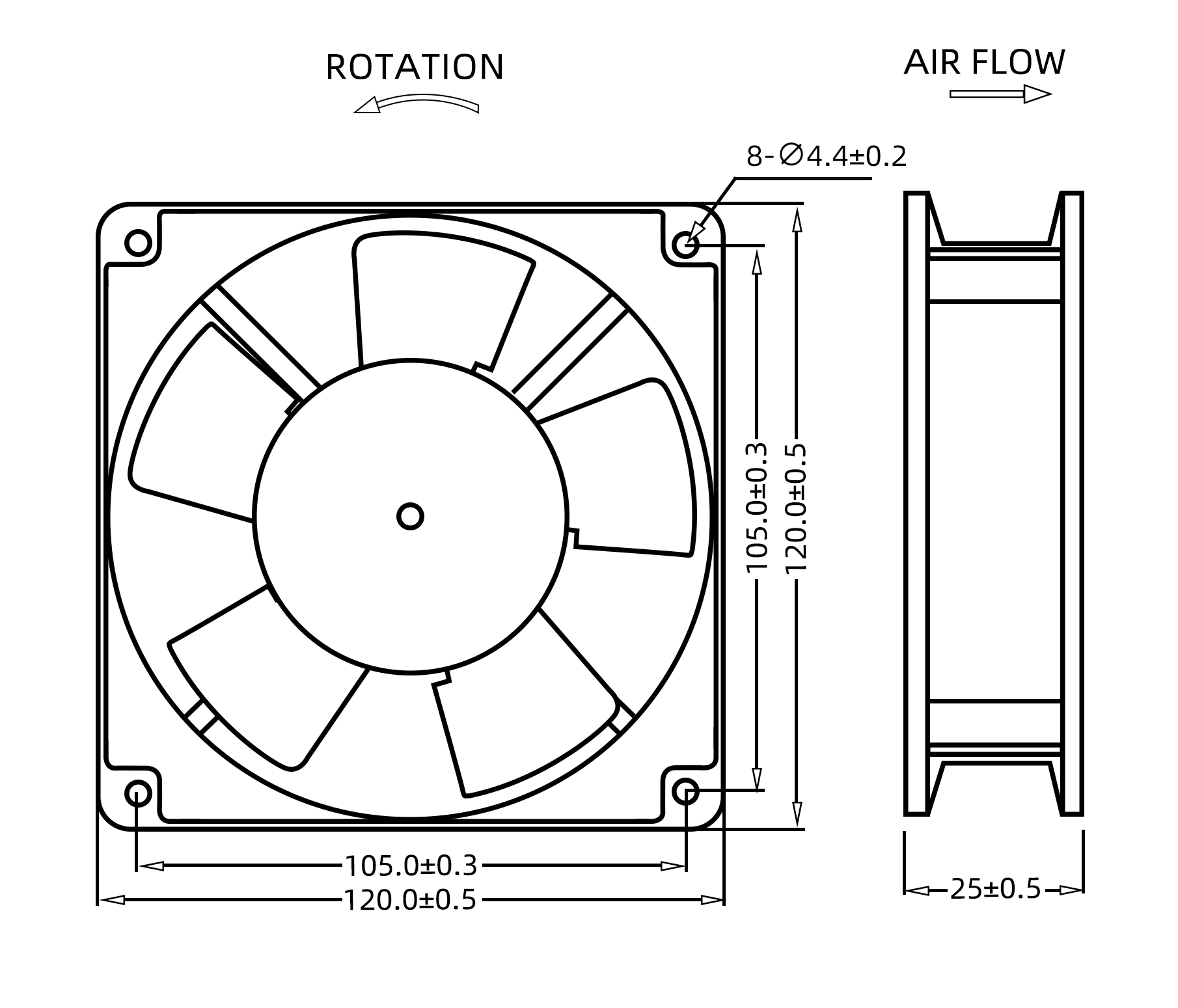

These fans feature a robust construction, typically composed of steel or aluminum materials for durability and corrosion resistance. Some models include protective grills, adjustable frames, or reinforced housings to ensure safe and stable operation.

3. Motor Options

The 200FZY axial flow fan is available with various motor types, including single-phase, three-phase, or explosion-proof motors, allowing adaptation to different power supplies and environmental conditions. Motor specifications influence airflow capacity, efficiency, and overall fan performance.

4. Noise Levels

Noise management is an important characteristic of axial fans. 200FZY models are designed with blade angles and motor placement optimized to reduce operational noise, making them suitable for indoor or noise-sensitive environments.

5. Portability and Mounting Options

These fans can be mounted in multiple ways, including wall-mounted, ceiling-mounted, or floor-mounted configurations. Their compact design and adjustable installation options enhance versatility for different spaces and ventilation needs.

6. Maintenance and Durability

200FZY fans are designed for easy maintenance, with accessible motor components and detachable blades for cleaning or replacement. High-quality materials and construction contribute to a long service life, even under continuous operation in demanding environments.

Types of 200FZY Axial Flow Fans

Several variants of the 200FZY axial flow fan are available, each optimized for specific applications:

1. Standard Axial Flow Fans

Standard models are designed for general ventilation purposes in factories, warehouses, and public buildings. They offer reliable airflow, moderate noise levels, and adaptability for various mounting options.

2. Explosion-Proof Axial Fans

Explosion-proof 200FZY fans are suitable for environments with flammable gases, dust, or chemicals, such as chemical plants or mining operations. These fans feature specially sealed motors and protective enclosures to prevent sparks and ensure safety.

3. High-Temperature Axial Fans

High-temperature models are capable of operating in environments with elevated temperatures, such as industrial furnaces or boiler rooms. Materials and motor components are selected to withstand heat while maintaining stable performance.

4. Low-Noise Axial Fans

Low-noise 200FZY fans are designed for indoor areas where noise control is important, such as offices, hospitals, or laboratories. Blade designs and vibration-reducing mounts minimize sound levels during operation.

Comparisons of 200FZY Axial Flow Fan Types

When comparing different 200FZY axial flow fan types, several aspects are noteworthy:

Airflow Capacity: Standard and high-temperature models offer high airflow, while low-noise models balance airflow with reduced sound.

Environmental Adaptation: Explosion-proof fans are ideal for hazardous conditions, whereas standard models are suitable for general ventilation.

Durability: High-temperature and explosion-proof fans use reinforced materials for conditions, while standard and low-noise models prioritize efficiency and convenience.

Noise Levels: Low-noise fans are optimized for quiet operation, while standard and high-temperature models may produce moderate operational sounds.

Installation Flexibility: All types can be wall, ceiling, or floor-mounted, but specific models may include additional features such as adjustable frames or protective cages.

English

English 中文简体

中文简体 عربى

عربى