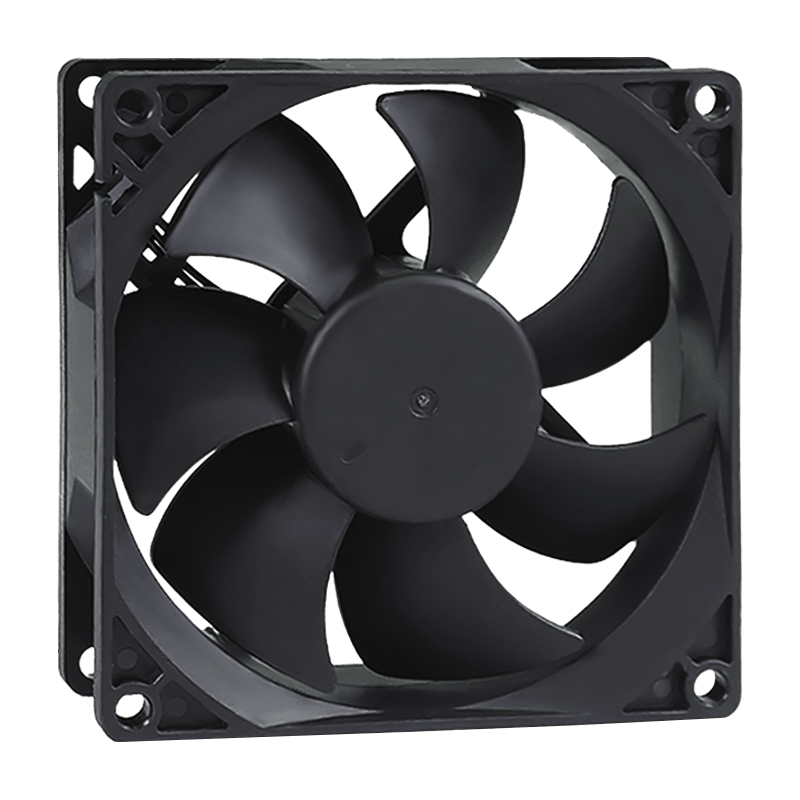

An axial flow fan operates by drawing air into the fan in the same direction as the axis of rotation, pushing the air through the fan and out in a straight line. This design is highly effective for applications requiring high airflow rates over low to moderate pressures. The 200FZY model is one of the prominent designs in axial flow fans, known for its durable construction and effective performance in various environments.

The model designation 200FZY provides key information about the fan's specifications:

200 refers to the diameter of the fan in millimeters, meaning the 200FZY has a blade diameter of 200mm.

FZY indicates the specific design series, which is typically associated with axial flow fans designed for industrial ventilation, cooling, and environmental control.

Key Features of 200FZY Axial Flow Fans

The 200FZY axial flow fan is engineered to deliver reliable performance in demanding conditions. Here are some of the standout features of this fan model:

1. High Airflow Efficiency

One of the primary advantages of the 200FZY axial flow fan is its ability to move large volumes of air with relatively low energy consumption. The fan blades are designed to optimize airflow, ensuring that a consistent and stable air movement is achieved even in high-demand environments. This makes it a go-to solution for applications that require efficient air circulation.

2. Durable Construction

The 200FZY fan is typically constructed from high-quality materials such as galvanized steel or stainless steel, which provide resistance to corrosion and extend the fan's service life. This durability makes it suitable for use in harsh environments where exposure to moisture, chemicals, or dust is common.

3. Low Maintenance

Due to its robust design, the 200FZY axial flow fan requires relatively little maintenance. The motor and bearings are designed for long-lasting performance, and the simple construction of the fan reduces the likelihood of mechanical failure, ensuring minimal downtime and maintenance costs.

4. Versatile Performance

The 200FZY fan can operate in a variety of environments, from industrial plants to commercial facilities. It is suitable for use in systems requiring continuous ventilation or cooling and can handle different airflow requirements depending on the specific installation.

5. Energy Efficient

Despite its high airflow capacity, the 200FZY axial flow fan is engineered to minimize energy consumption. This makes it a more sustainable and cost-effective option in the long term, helping businesses reduce their energy bills while maintaining high performance.

6. Noise Control

The design of the 200FZY fan also prioritizes noise reduction. The blade design and motor casing are optimized to produce minimal noise during operation. This feature makes it an ideal choice for applications where noise levels must be kept to a, such as in commercial spaces or residential areas.

Advantages of Using 200FZY Axial Flow Fans

The 200FZY axial flow fan offers several key benefits that make it an attractive choice for a wide range of applications. Here are some of the notable advantages:

1. High Performance in Tight Spaces

The relatively compact design of the 200FZY axial flow fan makes it an choice for installations where space is limited. Its ability to fit into tight or restrictive spaces without compromising airflow performance is a key feature for industries with limited real estate for ventilation systems.

2. Improved Energy Savings

With its energy-efficient motor and design, the 200FZY fan helps to lower operational costs over time. Efficient operation means that less power is consumed to achieve performance, which is a significant consideration for facilities looking to reduce their energy usage and carbon footprint.

3. Customizable to Various Applications

The versatility of the 200FZY fan allows it to be adapted for a wide range of uses. Whether it's for cooling electrical equipment, ventilating a factory, or circulating air in a large building, the fan can be integrated into various systems with ease. Customizations in terms of fan speed, motor type, and other features are available to meet the specific needs of the application.

English

English 中文简体

中文简体 عربى

عربى