Cooling fans are essential components in various applications, from household appliances to industrial machinery. One type of cooling fan that has garnered significant attention is the 220V cooling fan. These fans are designed to run on a 220V power supply, which is commonly used in many parts of the world, especially in regions such as Europe, Asia, and Africa. For those considering or already using 220V cooling fans, understanding the correct configuration is critical for ensuring efficient operation, energy savings, and performance.

A 220V cooling fan is simply a fan that operates on a 220V alternating current (AC) power supply. The fan works by moving air to cool an environment or system, typically using an electric motor. This voltage specification is common in many countries around the world, and it is different from the 110V power supply that is used in places like the United States and Canada.

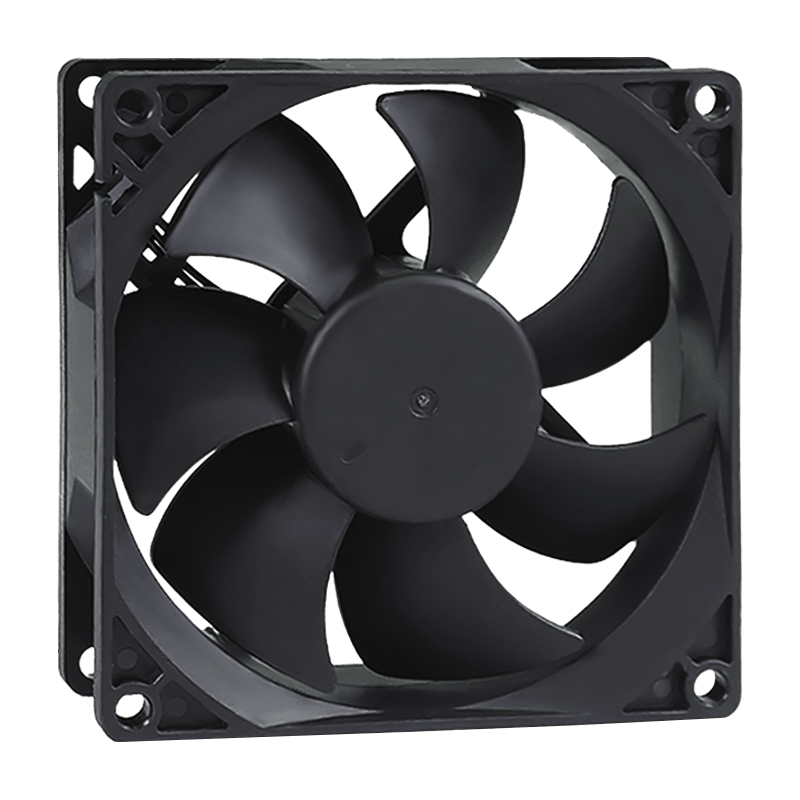

220V cooling fans are available in various designs, sizes, and functionalities, making them versatile enough for a wide range of applications, from cooling home appliances to industrial machinery. They are particularly popular for applications that require higher performance or where space-saving is a concern.

Key Components of a 220V Cooling Fan

Understanding the components that make up a 220V cooling fan can help you make informed decisions when configuring one for your needs. These components include:

1. Motor

The motor is the heart of the cooling fan. Many 220V cooling fans use an AC motor that operates on the 220V power supply. These motors are typically either single-phase or three-phase, depending on the application. A single-phase motor is generally used in smaller appliances and home applications, while three-phase motors are more common in industrial settings where higher power and efficiency are required.

The motor should be chosen based on the fan's required power output, as this determines the airflow and efficiency of the fan. Some fans come with variable-speed motors that allow users to adjust the fan speed for different cooling needs.

2. Blades

The fan blades are responsible for moving the air and creating the necessary airflow to cool the environment. The size, shape, and material of the blades influence the fan's efficiency, noise level, and airflow capacity. Larger blades typically move more air, but they may also generate more noise. Conversely, smaller blades tend to be quieter but may not provide as much airflow.

Blades can be made of various materials, including plastic, metal, and composite materials. The choice of material depends on the fan's application, with metal blades being preferred for high-performance, industrial cooling fans, and plastic blades being more common in household fans due to their lightweight nature.

3. Capacitor

In some 220V cooling fans, particularly those with single-phase motors, a capacitor is used to start the motor and ensure its smooth operation. The capacitor stores electrical energy and releases it to help start the motor and provide additional torque. Capacitors come in various sizes and should be matched with the motor to ensure performance.

4. Fan Casing and Mounting

The fan casing and mounting mechanism hold all the internal components together. The casing must be sturdy and designed to withstand the fan's operating environment, especially in industrial applications where the fan may be exposed to dust, moisture, or chemicals.

Mounting systems vary depending on the intended application. For example, wall-mounted fans or ceiling-mounted fans may require different mounting mechanisms than fans that sit on the floor or are installed in machinery.

5. Control System

Many 220V cooling fans come with a control system that allows users to adjust settings such as fan speed, direction of airflow, and timing. These systems are essential for tailoring the fan's operation to specific needs.

Control systems can range from basic on/off switches to more advanced electronic controllers with multiple speed settings, timers, or even remote controls. More sophisticated control systems may be integrated with sensors that automatically adjust the fan speed based on temperature or humidity levels.

English

English 中文简体

中文简体 عربى

عربى