Cooling fans are indispensable components in modern electronics, industrial equipment, and automotive systems. Among various voltage options, 24V cooling fans have gained significant popularity due to their balanced power consumption, compatibility with many control systems, and suitability for diverse applications. Over the years, the development of 24V cooling fans has reflected advances in materials, design, efficiency, and control technologies.

The initial adoption of 24V cooling fans was driven primarily by the automotive and telecommunications sectors. Many vehicle electrical systems operate on 24V to ensure reliable power delivery over long wiring harnesses and reduce current loads. Similarly, telecom equipment and industrial machinery often utilize 24V systems for control and power efficiency.

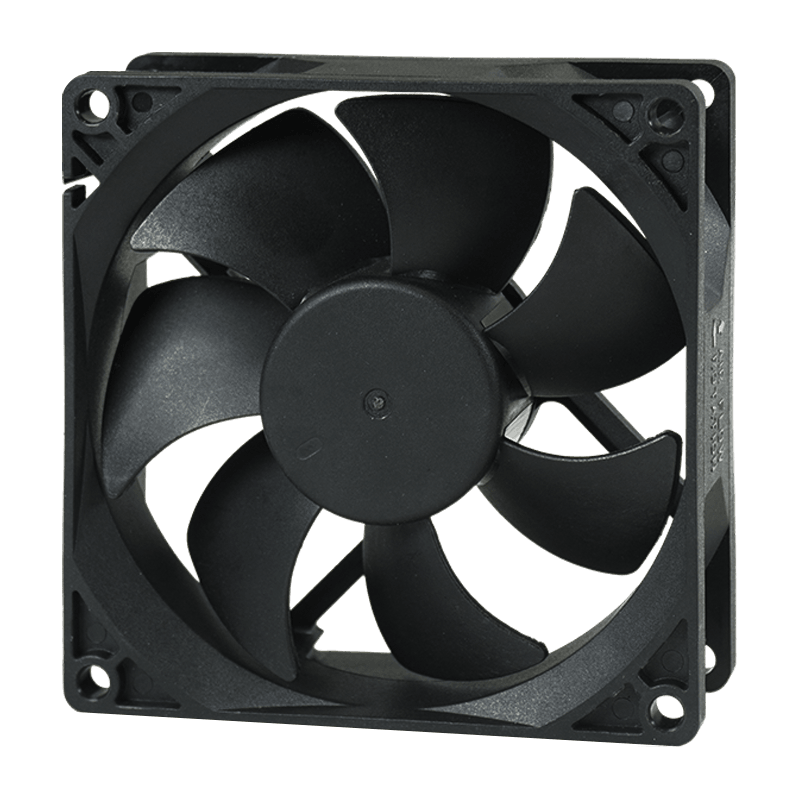

Early 24V fans were relatively simple devices, featuring brush-type motors and basic plastic or metal frames. Their design focused on basic air movement rather than optimized performance, and noise levels were generally high. These early fans met functional requirements but left room for improvement in durability, efficiency, and quietness.

One of the significant developments in 24V cooling fans has been the transition from brushed DC motors to brushless DC (BLDC) motors.

Brushed Motors: Initially common due to simplicity and low cost, these motors suffered from mechanical wear and limited lifespan because of brushes and commutators.

Brushless Motors: With electronic commutation, BLDC motors eliminate brushes, reducing maintenance needs, increasing efficiency, and improving reliability.

BLDC motors allow for precise speed control and quieter operation, making 24V fans suitable for sensitive electronics and continuous-duty industrial use.

Material technology has also evolved considerably. Early fans typically used basic plastics for frames and blades, which could degrade under heat or mechanical stress.

Modern 24V fans often utilize:

High-performance plastics (like glass-filled PBT): Offering heat resistance, mechanical strength, and flame retardance.

Aluminum or metal frames: For applications demanding structural rigidity and better heat dissipation.

Advanced bearing systems: Including ball bearings and fluid dynamic bearings that significantly extend fan life and reduce noise.

These material upgrades enhance operational reliability in harsh environments such as server rooms, automotive engine compartments, and industrial control panels.

The design of fan blades and housings has seen important refinements aimed at increasing airflow efficiency and reducing noise.

Blade Geometry: Use of airfoil-shaped and twisted blades enhances airflow with less turbulence.

Housing Design: Optimized to guide airflow smoothly and reduce vortex formation.

Noise Reduction: Incorporation of serrated blade edges or winglet tips to minimize aerodynamic noise.

Thanks to computer-aided design tools, manufacturers can simulate airflow and acoustic performance before production, ensuring 24V fans meet specific cooling and noise criteria.

The integration of electronics has further propelled the development of 24V cooling fans.

PWM (Pulse Width Modulation) Control: Allows users to precisely adjust fan speed according to temperature or load, improving energy efficiency and reducing noise.

Tachometer Feedback: Provides real-time fan speed monitoring for system diagnostics.

Thermal Sensors: Enable automatic fan speed regulation based on temperature readings, enhancing protection for sensitive components.

These features make 24V fans adaptable to dynamic thermal environments and critical for systems where efficient cooling and energy saving are priorities.

As 24V cooling fans improved in reliability and efficiency, their applications expanded significantly:

Telecommunications: Cooling for base stations and networking equipment.

Data Centers: High-efficiency fans supporting server racks.

Renewable Energy Systems: Cooling in inverters and battery management systems.

Electric Vehicles: Battery pack and motor cooling.

Industrial Automation: Control cabinet ventilation and machinery cooling.

English

English 中文简体

中文简体 عربى

عربى