Energy Efficiency and Power Consumption

One of the significant advantages of DC radiator fans is their energy efficiency. Unlike AC motors, which typically consume more power due to their continuous operation at a fixed speed, DC motors can adjust their speed based on the cooling needs of the system. This dynamic control over the fan's speed allows DC radiator fans to operate only when necessary, which reduces overall power consumption.

DC radiator fans can achieve higher efficiency because they are capable of operating at lower voltages and drawing less current when running at reduced speeds. For systems that require continuous or variable cooling, DC fans can significantly reduce energy consumption compared to AC fans, which usually run at a constant speed regardless of demand. This reduction in energy usage is not only beneficial for the environment but also for reducing operating costs in industries where cooling systems run continuously.

In automotive applications, for example, DC radiator fans are often used to cool engines or components that generate a lot of heat. These fans can be controlled by a thermostat or sensor, ensuring that they only operate when temperatures rise above a certain threshold, which further conserves energy. The ability to fine-tune fan speeds based on real-time cooling needs makes DC radiator fans highly energy-efficient.

Speed Control and Flexibility

DC radiator fans offer good speed control, a feature that enhances their versatility in various applications. By adjusting the voltage supplied to the motor, the speed of a DC fan can be easily varied. This allows for precise cooling control depending on the specific requirements of the system being cooled.

In comparison to AC fans, which generally run at a constant speed, DC fans provide the flexibility to operate at different speeds based on factors such as temperature fluctuations or cooling demand. For instance, in automotive applications, a DC radiator fan can increase its speed when the engine temperature rises, providing additional cooling. As the temperature decreases, the fan can reduce its speed or even turn off, saving energy and prolonging the life of the fan.

This ability to modulate speed makes DC radiator fans ideal for applications where cooling demands are not constant. In industrial equipment, for example, DC fans can be fine-tuned to meet varying levels of heat generation, ensuring that the system remains at operating temperatures while avoiding unnecessary power consumption.

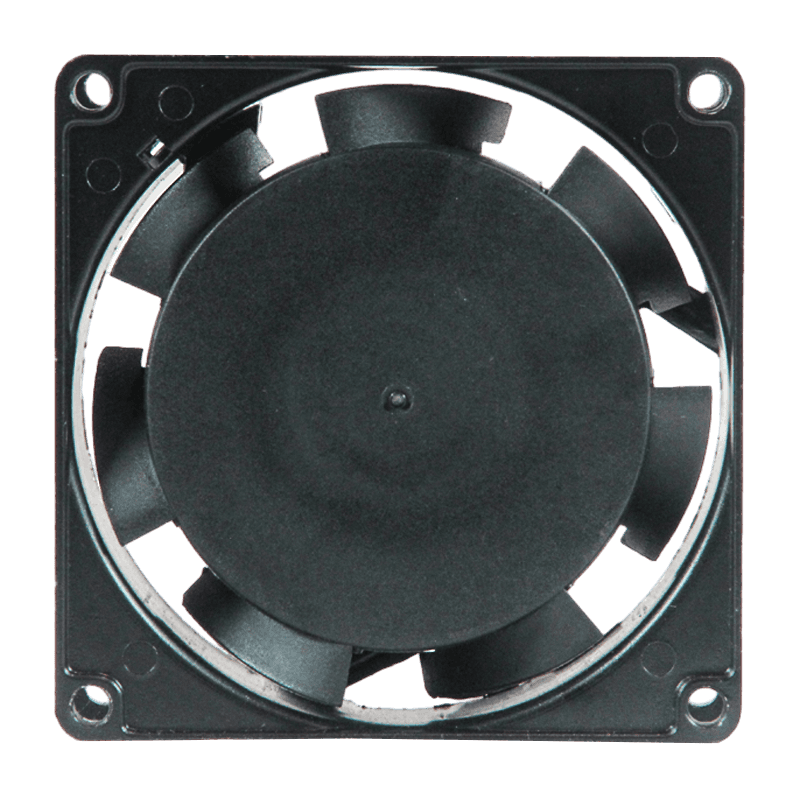

Compact Design and Space Efficiency

Another key feature of DC radiator fans is their compact design. DC motors are generally smaller and lighter than their AC counterparts, which makes them ideal for applications with limited space or weight constraints. The smaller size of the motor allows for a more compact fan assembly, which is particularly useful in industries such as automotive, electronics, and small machinery, where space is often at a premium.

The compactness of DC radiator fans also makes them easier to install and integrate into existing systems. In automotive cooling systems, for example, DC fans are often used in tight engine compartments where space is limited. Their smaller size allows for efficient airflow without taking up excessive room, which is essential for maintaining engine performance and preventing overheating.

Moreover, the reduced size and weight of DC fans contribute to the overall efficiency of the system by the impact on the overall load or power requirements of the device. Whether in a car, computer, or industrial machinery, the smaller footprint of a DC radiator fan helps to optimize the overall design and performance of the system.

Low Noise and Vibration

DC radiator fans are known for their quiet operation and reduced vibration levels compared to other types of fans, particularly those powered by AC motors. This is due to the nature of the DC motor, which produces less mechanical noise and generates less vibration during operation. The smooth and consistent operation of DC fans contributes to a quieter overall environment in both consumer and industrial applications.

In automotive cooling systems, for example, noise reduction is crucial for maintaining a quiet cabin environment. DC radiator fans operate with minimal noise, ensuring that vehicle occupants are not disturbed by excessive fan sound. This feature is especially important in electric vehicles (EVs) and hybrid vehicles, where noise is often a design priority.

In industrial machinery and electronic devices, low noise levels are equally important, particularly in environments where noise pollution can affect worker productivity or the operation of sensitive equipment. DC fans, with their quiet operation, are ideal for maintaining a peaceful working environment and reducing noise-related disturbances.

The reduced vibration of DC radiator fans also extends their lifespan by the wear and tear that typically results from mechanical stresses in traditional AC-powered fans. This quieter, smoother operation improves the longevity and reliability of the fan, reducing the need for frequent maintenance or replacement.

English

English 中文简体

中文简体 عربى

عربى