A 220V cooling fan is a device designed to move air using an electric motor powered by a 220-volt supply.

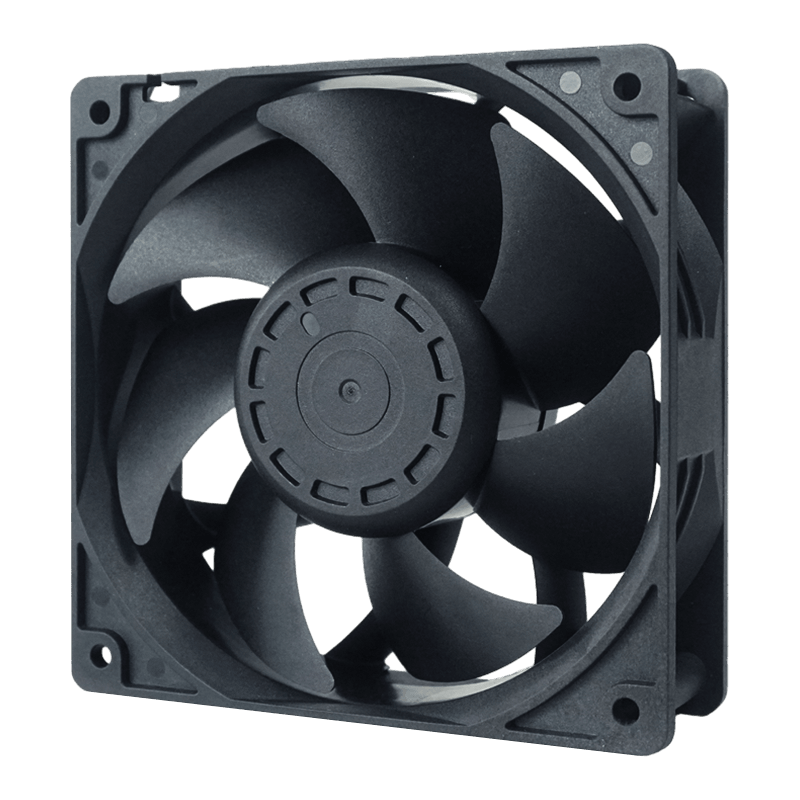

Structure: These fans typically consist of a motor, fan blades, housing, and a mounting frame. The motor converts electrical energy into mechanical rotation, which drives the blades to move air. The housing can be open, enclosed, or ducted depending on the application.

Function: The main function of a 220V cooling fan is to dissipate heat by generating airflow. It can be used to cool electronic equipment, industrial machinery, ventilation systems, or enclosed rooms where heat buildup may affect performance or safety.

Applications: 220V fans are commonly used in industrial control panels, server rooms, manufacturing equipment, air conditioning units, and commercial ventilation systems. Their higher voltage operation allows them to handle larger loads and provide continuous operation for extended periods.

What Types of 220V Cooling Fans Are Available?

220V cooling fans come in several types, each designed for specific applications and airflow requirements.

Axial Fans: These fans feature blades mounted on a central hub that push air along the axis of rotation. Axial fans are commonly used for general ventilation, cooling machinery, or moving air through ducts.

Centrifugal or Blower Fans: Blower fans direct air perpendicularly to the axis of rotation, creating high-pressure airflow suitable for confined spaces or ducted systems. They are often used in HVAC systems, industrial exhausts, and equipment cooling.

Wall-Mounted or Panel Fans: These fans are designed to be installed on walls, panels, or enclosures. They provide localized airflow and are often used for control cabinets, electrical enclosures, or server racks.

Industrial Floor or Ceiling Fans: Larger 220V fans designed for warehouses, workshops, or factories provide extensive airflow to regulate temperature over wide areas.

Function: The type of fan determines airflow pattern, pressure, and coverage area, allowing selection according to specific cooling needs.

How Do 220V Cooling Fans Operate?

The operation of a 220V cooling fan involves converting electrical energy into mechanical motion to move air.

Motor Function: When powered, the 220V motor rotates the fan blades. The rotation speed, determined by the motor design, controls the airflow rate.

Airflow Direction: Axial fans move air along the blade axis, while blower fans redirect airflow perpendicularly to generate higher pressure.

Control Methods: Many 220V fans are compatible with switches, thermostats, or variable frequency drives (VFDs) to adjust speed and airflow according to temperature conditions. This allows energy-efficient operation and temperature management.

Applications: Proper operation ensures consistent cooling of machinery, electronic equipment, and spaces, preventing overheating, equipment malfunction, or safety hazards.

How Should 220V Cooling Fans Be Maintained?

Maintenance is essential to ensure reliable operation, safety, and extended service life of 220V cooling fans.

Cleaning: Dust, dirt, and debris can accumulate on blades, motors, and housing, reducing efficiency and airflow. Regular cleaning prevents overheating and ensures performance.

Inspection: Periodic inspections should include checking blade balance, electrical connections, and motor condition. Loose components can cause vibration or mechanical damage.

Lubrication: Some 220V fans have bearings that require periodic lubrication to reduce friction and prevent wear. Follow the manufacturer's instructions regarding lubrication intervals and type.

Safety Checks: Ensure that all wiring and insulation are intact. Regularly check for signs of overheating, unusual noise, or vibration that may indicate electrical or mechanical issues.

Function: Proper maintenance helps maintain airflow efficiency, prevents electrical hazards, and reduces the risk of equipment failure or downtime.

English

English 中文简体

中文简体 عربى

عربى