Despite their broad application, 200FZY axial flow fans have several inherent shortcomings. One limitation is relatively low static pressure capability. Axial flow fans are designed to move large volumes of air in open or low-resistance environments. When installed in systems with long ducts, dense filters, or high back pressure, airflow can drop significantly, reducing cooling effectiveness.

Noise is another concern. Compared with smaller or lower-speed fans, 200FZY models can generate noticeable operating noise, particularly at higher rotational speeds. This is mainly due to blade air turbulence and motor vibration. While acceptable in industrial settings, it may be less suitable for noise-sensitive environments without additional sound-damping measures.

Energy efficiency can also be a limitation. Traditional AC axial fans, including many 200FZY models, are generally less energy-efficient than modern DC or EC fans. Continuous operation may result in higher power consumption over time, especially in applications where variable speed control is not available.

Environmental adaptability can be restricted. Standard 200FZY axial flow fans may have limited resistance to dust, moisture, or corrosive gases unless specifically designed with protective coatings or sealed bearings. In harsh environments, insufficient protection can shorten service life and increase maintenance requirements.

How to Correctly Understand and Use 200FZY Axial Flow Fans?

A correct understanding of 200FZY axial flow fans helps users avoid improper selection and premature failure.

Recognize their airflow characteristics

These fans are optimized for high airflow at low pressure, making them suitable for open ventilation rather than complex duct systems.

Match voltage and frequency accurately

200FZY fans are designed for specific AC voltage and frequency standards. Incorrect power supply can bring about overheating or unstable operation.

Ensure proper installation orientation

Airflow direction must align with system design. Incorrect mounting can reduce efficiency and increase noise.

Allow sufficient clearance

Adequate space around the fan inlet and outlet helps prevent airflow obstruction and reduces turbulence.

Consider operating environment

Temperature, dust levels, and humidity should remain within rated limits unless the fan is designed for special conditions.

Plan for maintenance access

Although axial fans have simple structures, periodic inspection and cleaning help maintain airflow and extend service life.

Understanding these points ensures that 200FZY axial flow fans are used within their design scope and deliver stable, predictable performance.

Application Suitability and Performance Expectations

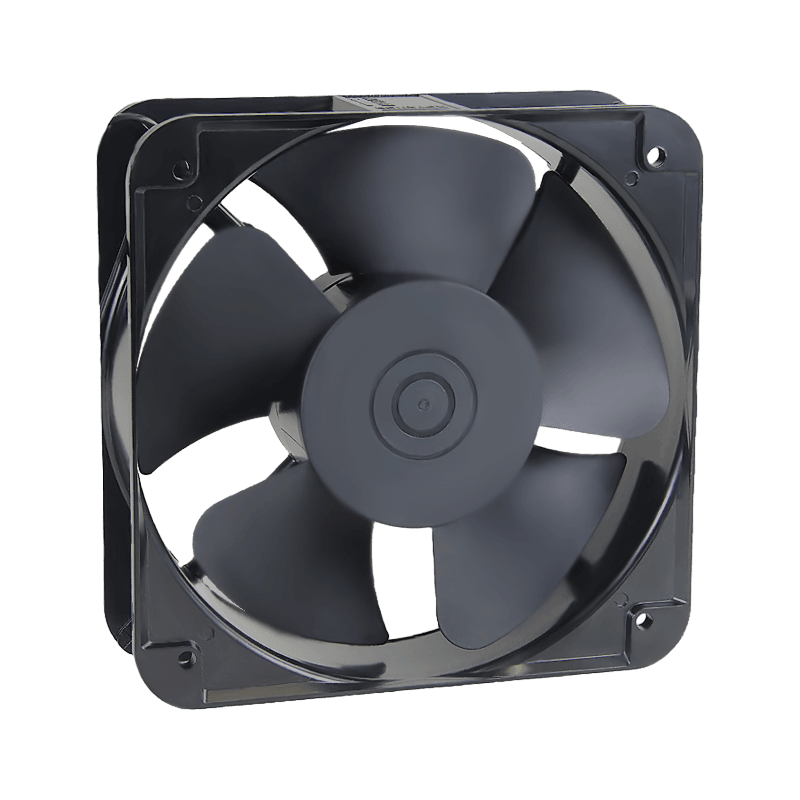

200FZY axial flow fans are well suited for equipment cooling and general ventilation where air resistance is minimal. Typical applications include electrical cabinets, inverter cooling, welding machines, and industrial enclosures. In these scenarios, their ability to move air efficiently across components helps maintain stable operating temperatures.

Performance expectations should remain realistic. These fans are not intended to replace centrifugal fans in high-pressure systems. When users clearly define airflow requirements and environmental conditions, 200FZY fans can provide reliable service without unnecessary oversizing or energy waste.

Additionally, users should consider duty cycle requirements. Continuous operation is generally acceptable, but operating close to temperature limits for extended periods can accelerate bearing wear. Selecting a fan with a suitable safety margin improves long-term reliability.

Reliability, Maintenance, and Selection Factors

Reliability depends heavily on bearing type, material quality, and operating conditions. Many 200FZY axial flow fans use ball bearings, which offer better durability under continuous operation compared with sleeve bearings. However, even ball-bearing fans require clean airflow to achieve their rated service life.

Maintenance is relatively straightforward. Regular cleaning to remove dust buildup helps preserve airflow and reduce motor load. Electrical connections should be checked periodically to prevent overheating caused by loose terminals.

When selecting a 200FZY axial flow fan, users should review parameters such as airflow rating, noise level, power consumption, insulation class, and protection grade. Choosing a model that aligns with actual operating conditions rather than specifications often results in better efficiency and longer lifespan.

English

English 中文简体

中文简体 عربى

عربى