What are the components of 200FZY Axial Flow Fans?

A 200FZY axial fan is an integrated electromechanical assembly. Its key components work together to generate airflow.

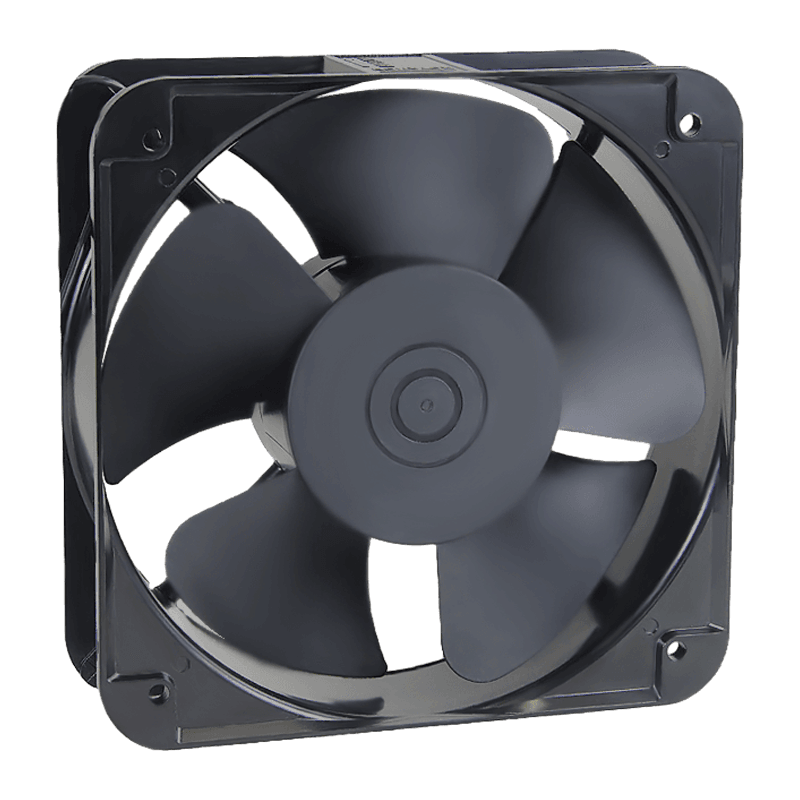

Impeller (Propeller): This is the rotating blade assembly, directly responsible for moving air. It consists of a central hub and multiple airfoil-shaped blades, typically made from molded plastic (like ABS or PP), aluminum, or steel. The blade angle, count, and diameter are designed to achieve specific performance parameters.

Motor: An AC or DC electric motor provides the rotational power. In many direct-drive axial fans, the motor is integrated into the fan's central housing, with the impeller mounted directly onto the motor shaft. The motor is rated for a specific voltage, frequency, power, and speed (RPM).

Housing (Casing or Shroud): A cylindrical or venturi-shaped structure, usually made from stamped steel, aluminum, or plastic, that surrounds the impeller. It guides the airflow, improves aerodynamic efficiency, and provides a mounting structure. It also incorporates safety guards to prevent contact with the blades.

Mounting Frame and Brackets: A rigid framework, often made from steel wire or stamped metal, that supports the motor and housing assembly. It provides the points for installing the fan into an opening, duct, or equipment panel.

Terminal Box and Wiring: A protective enclosure where the motor's power leads are connected to the external supply wiring. It may include a capacitor for single-phase AC motor startup.

Protective Grilles: Wire mesh or perforated metal screens installed on the inlet and/or outlet sides of the fan to protect fingers and objects from the rotating blades and to prevent large debris from entering.

Why do 200FZY Axial Flow Fans exist?

Well-defined needs in thermal management and air exchange drive the development and specification of this fan series.

Providing High-Volume, Low-Pressure Airflow

Axial fans, including the 200FZY series, are designed to move large volumes of air against relatively low static pressure resistance. Their primary purpose is to perform tasks where the main requirement is to exchange or move air across a short distance or through an open space, such as general room ventilation, spot cooling of equipment, or exhaust applications where ductwork is short and straight.

Cooling Electronic and Electrical Enclosures

A common application is in the thermal management of electrical cabinets, control panels, and industrial machinery. The 200FZY size is often suitable for mounting on standardized panel cutouts. The fan draws cooler ambient air across heat-generating components like variable frequency drives, power supplies, or transformers, preventing overheating and ensuring reliable operation.

Ventilation in Confined Industrial Spaces

These fans are used for extracting fumes, removing mild dust, or providing fresh air intake in workshops, agricultural buildings, and commercial kitchens. Their ability to move substantial air volumes makes them effective for diluting airborne contaminants and regulating temperature in such environments where creating high static pressure is not the primary challenge.

Technical Issues of 200FZY Axial Flow Fans

Several performance and reliability challenges are inherent to the axial fan design and its operating environment.

Performance Limitation in Ducted Systems: The significant technical issue is their sharp performance decline when faced with increased static pressure. Axial fans are inefficient at pushing air through long duct runs, restrictive filters, or heat exchangers. As system resistance rises, the airflow delivered by a 200FZY fan can drop significantly. For such applications, a centrifugal fan, designed to generate higher pressure, is often more appropriate.

Noise Generation: Axial fans can produce noticeable aerodynamic and mechanical noise. Aerodynamic noise comes from turbulence caused by the blade tips interacting with the air and the housing. Mechanical noise originates from motor bearings and impeller imbalance. This makes them less suitable for noise-sensitive environments unless specifically designed as low-noise models, which may use slower speeds, different blade geometries, or sound-absorbing materials.

Sensitivity to Inlet/Outlet Conditions: Their performance is highly dependent on unobstructed, smooth airflow at the inlet. A restricted inlet (e.g., a fan mounted flush against a wall without adequate clearance) can cause turbulent inflow, drastically reducing airflow and efficiency, and increasing noise. Similarly, an abrupt bend or obstruction immediately at the outlet can create back-pressure and recirculation, impairing performance.

Bearing Wear and Motor Overheating: The integrated motor bearings are subject to wear, especially in dirty or high-temperature environments. Dust accumulation on the impeller can cause imbalance, bring about vibration and accelerated bearing failure. If the fan is operated in a system with higher-than-designed static pressure, the motor may draw more current and overheat, potentially bring about insulation failure and burnout. Ensuring clean operating conditions and selecting a fan with adequate pressure head for the actual application are necessary to mitigate these issues.

English

English 中文简体

中文简体 عربى

عربى