Design and Structural Features

From a design perspective, EC cooling fans combine the features of traditional AC and DC fans with an integrated electronic control system. The core components include a brushless DC motor, fan blades, a housing unit, and an internal control circuit. The brushless motor eliminates the need for mechanical brushes, reducing friction and wear over time. The electronic control module adjusts motor speed, monitors voltage, and regulates current according to operational requirements.

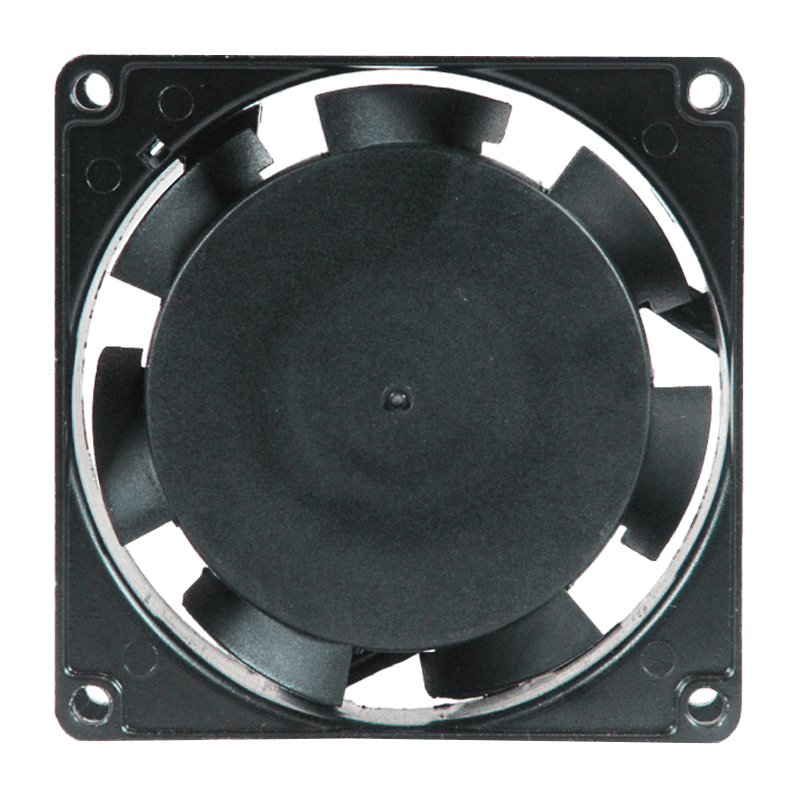

The fan blades are typically shaped to provide efficient airflow while reduce noise and turbulence. The housing can be constructed from metal or high-strength plastic, providing structural support and protection for internal components. Some models include additional features such as vibration-damping mounts or protective grilles. These design elements allow EC cooling fans to operate continuously under varying load conditions while maintaining reliability and stability in airflow.

Operational Principles

EC cooling fans operate using electronically controlled brushless motors. Unlike conventional AC fans, EC fans use a control circuit to convert AC supply into a DC signal suitable for motor operation. The electronic commutation allows precise control of motor speed and torque without manual adjustments or external devices.

The fan’s operation is based on feedback from internal sensors, which monitor parameters such as rotational speed, voltage, and temperature. The control system adjusts the motor automatically to maintain the desired airflow or cooling effect. This precision improves energy efficiency because the fan operates only at the level necessary for the application rather than at a constant speed.

Additionally, the electronic controls can integrate with building management or industrial systems. For example, EC cooling fans can respond to external signals such as temperature or pressure changes, enabling automatic adaptation to environmental conditions.

Applications and Industry Uses

EC cooling fans are widely applied in industries and equipment where controlled cooling and energy efficiency are important. In HVAC systems, they provide ventilation and temperature management for commercial and industrial spaces. By regulating airflow based on demand, they support climate control without excessive energy consumption.

In electronics and data centers, EC cooling fans are used to manage heat generated by servers, power supplies, and control panels. Consistent airflow prevents overheating, supporting the safe operation of sensitive electronic components.

Industrial machinery, including compressors, pumps, and manufacturing equipment, also benefits from EC cooling fans. These fans maintain stable operating temperatures, prolonging the life of mechanical and electronic components. In all applications, their capacity for variable speed operation allows them to meet different cooling requirements efficiently.

Advantages and Practical Benefits

EC cooling fans offer several advantages compared with conventional AC or DC fans. One advantage is energy efficiency. The electronic control allows the fan to operate only at the speed necessary for a specific cooling demand, reducing unnecessary power consumption. This is especially relevant in continuous operation scenarios, such as data centers or industrial HVAC systems.

Another advantage is extended operational life. The brushless motor design reduces mechanical friction, decreasing wear on moving parts and supporting longer periods of continuous operation. This also reduces maintenance requirements.

EC cooling fans provide precise airflow control. Variable speed operation allows users or automated systems to adjust airflow accurately to match cooling needs. This flexibility improves system performance and can reduce noise, as the fan does not always operate at speed.

EC fans support system integration. They can communicate with external controls and respond to temperature or pressure inputs, which allows coordinated operation across multiple fans or with other building management equipment. This capability enhances efficiency, reliability, and environmental control.

English

English 中文简体

中文简体 عربى

عربى